Since founding, the Group focuses on providing the best packaging solutions for the China market. Our sales and engineer teams have deep experiences working in different industries and providing customized solutions that fully meet our customer’s packaging requirements. The Group is one of the few companies in the paper packaging industry that can offer packaging design, manufacturing, lab testing, on-site service and other value-extended services to the clients. Our customers are reputable companies in industries such as telecommunications, medical equipment,electronics, automotive, food & beverage and FMCG (Fast Moving Consumer Goods).

-

Packaging Solution for the Wallstand in the Medical Industry

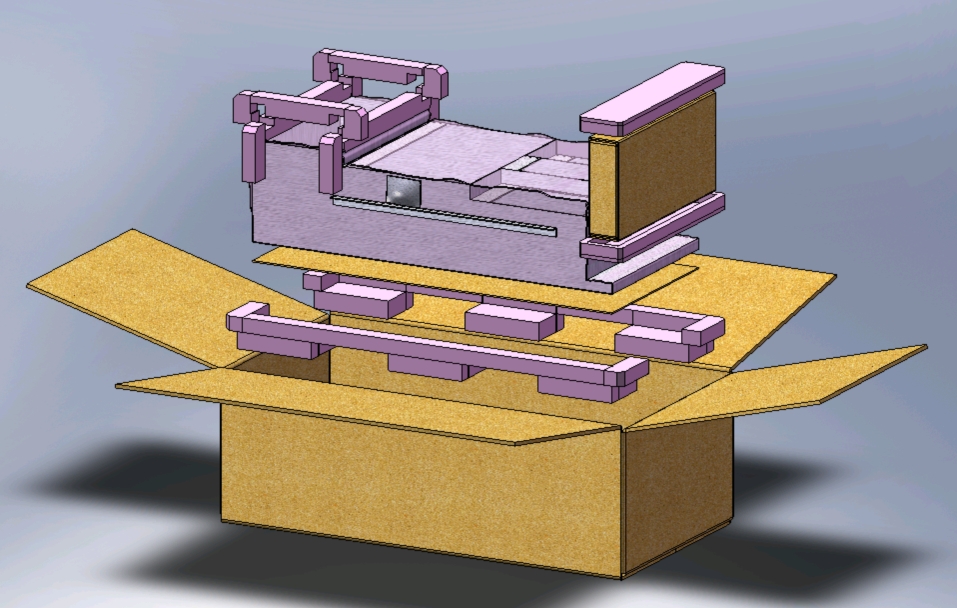

Wallstand is one of the examination and probing medical equipments for hospitals. Due to its irregular shape, excessive height, uneven weight, and heaviness, packing procedure in the manufacturing process was complicated and inefficient. Our engineers proposed to replace a poly-board frame with heavy-duty corrugated board made of kraft liner, which allowed for more flexibility in the overall design, and applied a hydraulic power steering system hinged with the base inspired by the mechanism of car trunk lifting. Our solution improved safety during the packaging process by eliminating the manually operated lifting gears and enhanced efficiency overall, especially for the end-users when they install the machine in examination rooms. The new packaging design has been well received by both the manufacturer and end-users.

-

Packaging Solution for Base Station Cabinet in the Tele-Communication Industry

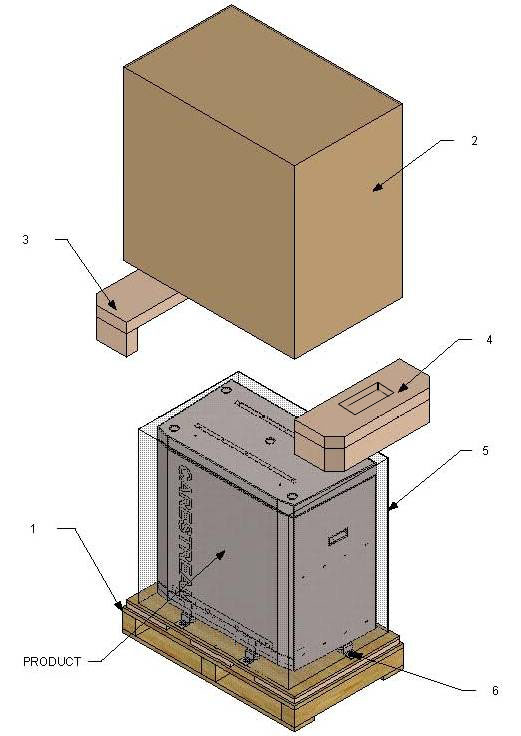

Mobile telecommunication cabinets are commonly used in the telecommunications industry. The equipment manufacturers set very high quality standard for the cabinet’s packaging to ensure the equipment is well protected during the logistics process. Our engineers developed a series of packaging solutions for Network Stations, Digital Program-Controlled Equipment, Mobile Data-Exchange Equipment, and RF models. Considering most of the products are shipped via air-cargo, our solution replaced poly-wood packing materials with a low weight but high strength corrugated board. The design then changed the structure of EPE cushion foam, resulting in 2 layers of buffers. The new design further inserted a high-density foam between the base of the pallet and the standing core of the product, giving it a 3rd layer cushion, which acted as a shock absorber during shipping. Aside from added protection, the advantage of our solution was the comprehensive cost saving involved in packaging materials, logistics, and labor cost related to handling disposable packaging materials. With extra protection and lower costs, our solutions allowed our customers to increase their competitiveness in the market.